Stories from Trego tunnel deviate from historical record

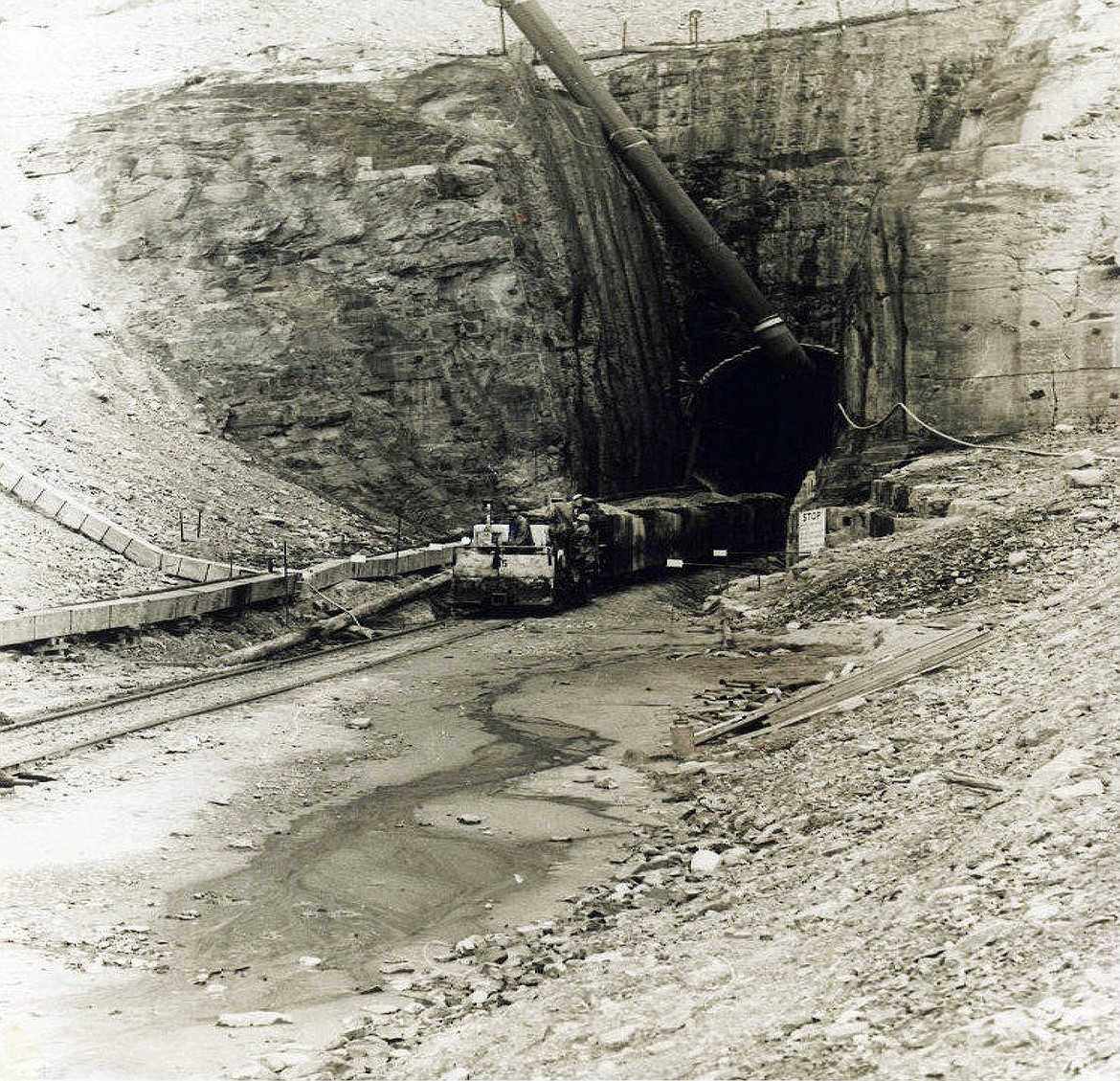

For the last nine months of the drilling phase of construction of the Flathead Railroad Tunnel near Trego, a then 19-year-old Bruce Morse took his camera with him as he joined his fellow workers more than three miles deep inside the Salish Mountains north of Whitefish.

Working between 1967 and 1968, Morse was a member of one of the three 20-man crews working around the clock on the tunnel’s south portal.

When Morse, of Edmonds, Washington, saw the Daily Inter Lake’s Jan. 16 article recounting the construction of the tunnel, the memories from more than half a century ago began flooding back to him.

Joining his father Herb, a diesel mechanic who had secured him the job, on the engine the pair made their first trip into the tunnel to work together.

“When you rode in there, you would look back and just watch that portal getting smaller and smaller,” Morse recalled. “About a mile in, you couldn’t see your hand in front of your face anymore. There was just no light whatsoever beyond that point.”

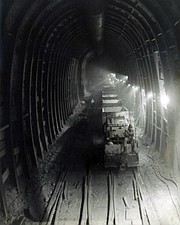

Awaiting them at the end of their miles long ride over the tunnel’s crooked and bumpy temporary rail system was the impressive jumbo, a three-story-tall, 40-ton contraption that slowly inched its way through the mountain carrying the more than one dozen drills that excavated holes for explosives.

Three times per shift and nine times each day, the jumbo was moved away from the rock face, the lights were extinguished and the workers waited in the constant 55-degree absolute darkness for the rhythmic thump, thump, thump as a series of 10 explosives were detonated to demolish another section of the mountain.

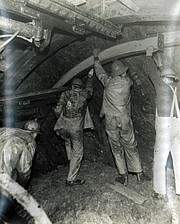

Once the process was complete, the lights would come back on and the crew would set to work clearing, or “mucking” out the debris in a train of ore cars, installing the 42-foot tall metal archways that supported the ceiling and walls and drilling the holes for the next set of explosives.

IT WAS dirty and dangerous work.

“[Occupational Safety and Health Administration] would hang the company today for the conditions we were working in back then,” Morse laughed. “The air was just filled with this blue haze, and it was oil. The oil was injected into the compressed air line to lubricate the drills and then it would come out in the exhaust. With all of the drills working, the air would be filled with those fine oil particles. We wore yellow slickers and the oil would just be flowing off you. That’s why they had showers onsite. It was awful.”

While the hard-rock drilling conditions meant the workers were safe from the dangers posed by fine dust particles, there were many other dangers the crews had to contend with.

According to the government’s reports on the project, two men were killed during the tunnel’s construction, but Morse claims there were several more that did not make the official report.

One incident involved two drill operators who inadvertently drilled into a section of undetonated explosives and another worker died when a large section of rock fell from the ceiling, crushing him.

While those were the only three deaths Morse could recall, he said there were several other close calls.

“One day, someone did not hook the compressed air hose together correctly and when they turned on the air it started whipping back and forth like a snake from side to side in the tunnel,” he said. “It didn’t kill the guy, but it knocked him over, flat. It was wild.”

ANOTHER INCIDENT involved a narrow escape by the entire crew.

“There was a rock blast when the two sides were getting close to each other, maybe half a mile apart, when my dad was standing next to the air hose. My dad shut off the air hose and the shift boss started yelling at him. My dad told everyone to shut up and then told us all to get out. We all scrambled off the jumbo and onto the motor and started backing out of there. As we backed out, the whole side of the tunnel blew in where we had been working,” Morse recalled. “It sounded like a bomb had gone off and there was a rush of wind that nearly knocked us all off that motor. My dad had felt the vibration before it all gave way. I was never so happy to see the outside in all my life. Then, the next day, we went back in there and found it had blown out perpendicular to the tunnel and created a hole that went back nearly a quarter of a mile. It took us six weeks to clean that out and get the jumbo rebuilt.”

Morse recalled other moments that never made it into the government’s report on the project.

“One time when they turned the lights on after blasting, we just stood there in shock because there was a line across the face, called a chimney, that was full of silver,” he said. “It just glistened in the light. We all ran up there with our picks and took what we could before we got back to working.”

A DEPARTURE from the official history of the tunnel involved the final explosion that connected the two teams drilling into the mountain. Morse said the two crews actually connected several days before the official “tunneling through” ceremony.

“As we got closer and closer to each other, you could hear and feel the thumps of the explosions from the other crew,” he said. “When we were really close, one of the guys drilled through and started yelling that he had punched through. We pulled the drill out and shined a flashlight down the hole and saw an eyeball at the other end staring back at us.”

The construction company’s higher-ups decided to wait three days before conducting the final blast on June 21, 1968, during a special ceremony where President Lyndon Johnson could initiate the explosion with the push of a button from the White House.

History says that is exactly what happened, but Morse tells a different story.

“I remember, LBJ says here we go and he hit the button, and nothing happened,” Morse said. “The quick-thinking shift boss grabbed the telephone wire and hooked it up to the plunger and blew the charges. We heard the President ask if it had worked and we just told him that it had. We totally faked it.”

FOLLOWING MORE than two years of tunneling, and nine months of work from Morse, the tunneling was complete.

The project was fully completed on Nov. 7, 1970, when the tunnel was placed in service.

With the construction company providing housing, showers and food, Morse said he didn’t cash a single check the entire time he worked on the project. At $300 per week (slightly less than $2,500 in today’s money), Morse made enough to buy himself a 1963 Chevy Impala and fully pay his way through college at the University of Montana.

“It was pretty boring in some ways. You would drill with a lot of noise, air pressure and oil in the air,” he said. “But, it was a high ball, ramrod, get in there and get it blasted then get the rock out kind of operation. It was go, go, go — so what if I guy gets killed, get someone else up there operation. It was a real reality check for me, but I am glad I did it.”

Reporter Jeremy Weber may be reached at 406-758-4446 or jweber@dailyinterlake.com.