Returning to the forge — New Agrarian School in Bigfork revives the ancient trade of the blacksmith

The New Agrarian School in Bigfork, a nonprofit, teaches the ancient craft of blacksmithing to a new generation of hobbyists, professionals, and instructors.

While blacksmiths historically produced common everyday items from hammers to horseshoes, modern practitioners can focus on decorative and sculptural work. Many people are also drawn to the craft for the satisfaction of forging functional tools such as knives and axes, using heat and hammers.

New Agrarian School Founder Jeffrey Funk discovered his passion for blacksmithing at 18 when he purchased his first anvil and built a decades-long career in the trade. In 2019, he opened the school to preserve and pass on the craft.

“Any time you need a tool you can just make it, which is pretty satisfying,” Funk said, including crafting a scythe when he decided to start growing and harvesting his own wheat. “Being able to make the basic things you might require for your sustenance is, it’s pretty empowering.”

Funk’s career has included architectural and commissioned work such as gates, railings, light fixtures and sculptures, including one installed in Tennessee.

"Blacksmithing as a necessary economic craft basically dissolved in the early part of the 20th century. In small towns, there were blacksmiths into the mid-20th century, but it was essentially dead, or in hibernation, by the 1950s,” he said.

Between the East Coast craft schools and organizations such as the Artist-Blacksmith’s Association of North America, there’s been a resurgence of interest.

“Fifty years later and it’s actually a pretty vital craft. It mostly concerns people making architectural metalwork, toolmaking and knifemaking. Those are the primaries," he said.

The New Agrarian School, modeled after East Coast craft schools, aims to fill a need for formal blacksmithing education in the West, according to Funk. The school's approach emphasizes traditional techniques and a deep understanding of materials.

"If [enrollment in] the schools in the East are any indication — it fulfills a need,” he said.

On a cool fall November day, Funk provided a tour of the New Agrarian School, which offers one- to two-week workshops in the summer. Funk spends the fall and winter months working on personal projects and preparing for summer workshops.

A small gravel parking lot opens to the school and blacksmith shop, which was featured in an episode of the History Channel reality show “Forged in Fire.”

Metalwork is found throughout the property and for the most part has been repurposed from something else — namely bridges.

“The shop’s built from a bridge that was down the road, Kearney Rapids Bridge, which was taken down in the ’90s,” he said, pointing toward columns and beams.

A student-created sculpture decorates the yard in front of a small brick library with a porch held up by metal columns. The sculpture was made with the repurposed parts of the “old steel bridge,” which is actually wrought iron Funk said, a staple for blacksmiths.

“Wrought iron is not a modern material. It’s related to steel. It has to do with the way it was manufactured," he explained. “I use that material for everything, and I salvage the bridges because it’s just a really wonderful material.”

“Some of these materials simply aren’t available. So, I’m looking to get one more bridge I think,” he said, eyeing the Bigfork bridge slated for replacement on Bridge Street.

He said wrought iron is very soft, making it easy to forge and weld. Welding in blacksmithing is a different process than what’s done in a fabrication shop.

“By heating your pieces to the proper temperature and actually just hammering them together,” Funk explained, versus an arc weld, for example, which uses an electric current to heat the metal.

Inside, the blacksmith shop is far from the darkened, sooty depictions or historical recreations. He said that’s due to using a propane-powered forge. As a school, he said it was important to have an environment that was clean and orderly for students to move around safely.

“I quit using coal in the ’80s. That was kind of romantic for a little while, but I wanted to be able to breathe,” Funk said.

All the tools that students use in the shop are a model of self-sufficiency as they were hand-crafted. Funk also built enormous air-powered hammers that students get to use.

“There’s been quite a bit of innovation in this shop for the way of making tools. We make our own sledgehammers, we make everything,” he said.

Turning one of the power hammers on, the hiss of whooshing air can be heard as the hammer swiftly drives up and down.

“The larger material you need more power," he said, or a sledgehammer-wielding shop assistant at the ready. “And they’re all different sizes. Like this is 500 pounds, that’s 400 pounds and this is a 200 pound [hammer].”

Around the shop are demonstration pieces and panels, he refers to as storyboards, showing the different states or stages of a particular process or technique. One panel shows what occurs with different heat treatments.

Picking up a steel rod, he does a quick demonstration for photos. Placing the rod into the neon red-orange glow of the forge he heats it up just enough to start hammering the end into a point. After a few minutes, he decides it needs to be heated up longer, wanting to use one of the power hammers. Funk nimbly rotates the rod sandwiched under the hammer to create a more defined point.

“This year, there's going to be the fundamentals class they'll make probably hooks and pokers and small items like that. The blacksmith’s tools class they’ll make hammers and tongs and anvil tools,” he said.

FOR STUDENT Tug Leberman, a retired contractor and carpenter, his interest in learning blacksmithing started out with the need for antique-style square-headed nails for a woodworking project on a chuckwagon.

“Being a frugal guy, I thought how hard could it be to make myself?” said Leberman, who has done woodworking since he was 14 and uses traditional hand tools.

After doing some research, he realized YouTube videos wouldn’t cut it and reached out to various blacksmiths.

“The difference with metalworking is there’s a lot more mathematics involved,” he said.

He eventually found/connected with Funk, who had not yet opened the New Agrarian School at the time. Leberman said Funk was generous enough to give him a crash course in blacksmithing that once the school opened Leberman was ready to take a deeper dive, starting with the basics and was hooked. He’s since taken multiple workshops at the school, the latest being an ax-building workshop.

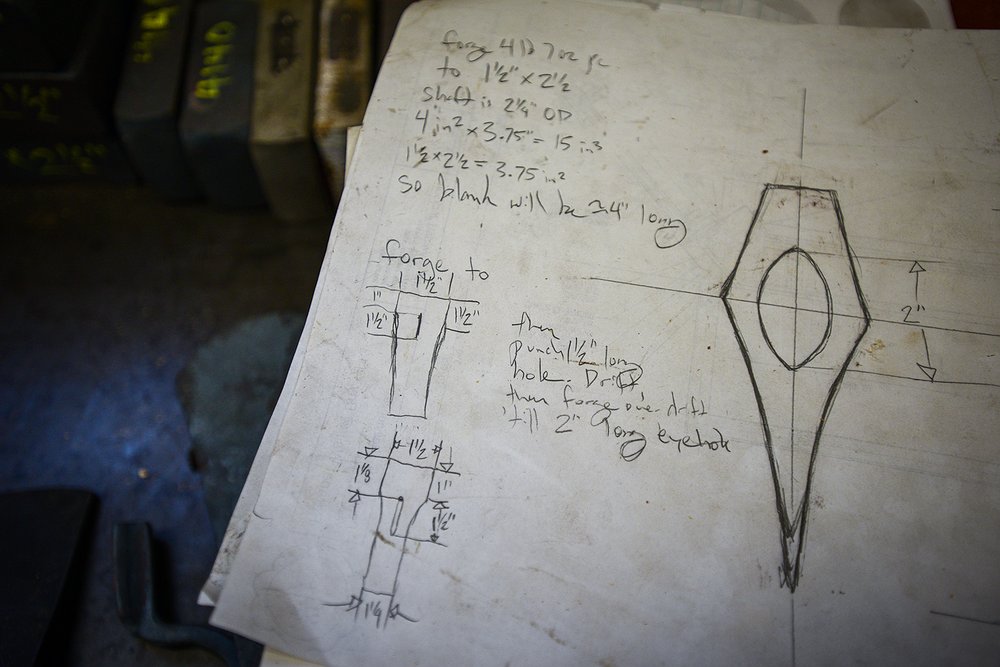

“It doesn’t sound complicated but when you see it done — when you get into it — it’s probably 25 to 30 steps,” Leberman said.

In-kind, Leberman shared his woodworking expertise and tools with Funk.

“I am fascinated with what you can make with the most primitive tools,” Leberman said.

With the school officially notified of its nonprofit status this year, Funk begins the work of fundraising to sustain the school. Currently, he pays costs not covered by tuition. The nonprofit status also allows Funk to seek grant funding.

He said if there is enough interest, the next step may be expanding into other areas such as timberwork, ceramics, or fabrics, mirroring that of the Penland School of Craft in North Carolina.

“I think craft schools are much better if there’s more than one craft going on because there’s a cross-pollination between the different crafts,” he said.

Registration for summer 2025 workshops is open. June workshops include Blacksmithing Fundamentals with Tony Stewart and Hammers and Tongs with Funk and Knives for the Outdoors with Jordan LaMothe.

In July, Funk will teach Forging from the Natural World and Tools for Farm and Garden. From July 28 through Aug. 1, Mark Aspery will teach blacksmithing for advanced beginners to intermediate-level students. August workshops also include Utensil Forging: Design and Refine with Anna Koplik; American Axes with Funk and Zen and the Art of Hammer Swinging with Peter Braspenninx.

Tuition for two-week workshops is $1,950 and $975 for one-week workshops. Various on-site accommodations are available for students to book separately.

To register for a workshop; donate; or for more information, visit www.newagrarianschool.org.

Reporter Hilary Matheson may be reached at 758-4431 or hmatheson@dailyinterlake.com.

Jeffrey Funk shows two sample bars of wrought iron inside his office that have been deeply etched in acid to remove slag and reveal grain. The bar on the left is from wrought iron from the Old Steel Bridge, which used to span the Flathead River in Evergreen. The bar on the right is iron smelted from ore in his workshop. (Casey Kreider/Daily Inter Lake)

Jeffrey Funk shows two sample bars of wrought iron inside his office that have been deeply etched in acid to remove slag and reveal grain. The bar on the left is from wrought iron from the Old Steel Bridge, which used to span the Flathead River in Evergreen. The bar on the right is iron smelted from ore in his workshop. (Casey Kreider/Daily Inter Lake) An axe with a New Agrarian Tools label inside Jeffrey Funk's workshop in Bigfork on Tuesday, Nov. 12. (Casey Kreider/Daily Inter Lake)

An axe with a New Agrarian Tools label inside Jeffrey Funk's workshop in Bigfork on Tuesday, Nov. 12. (Casey Kreider/Daily Inter Lake) Students taking a June iron smelting class from the New Agrarian School in Bigfork pose for a class photo by a bloomery furnace. The class made iron from a variety of ores sourced in Montana and Utah. (Photo provided by Jefferey Funk)

Students taking a June iron smelting class from the New Agrarian School in Bigfork pose for a class photo by a bloomery furnace. The class made iron from a variety of ores sourced in Montana and Utah. (Photo provided by Jefferey Funk)